Computer numerically controlled (CNC) punching

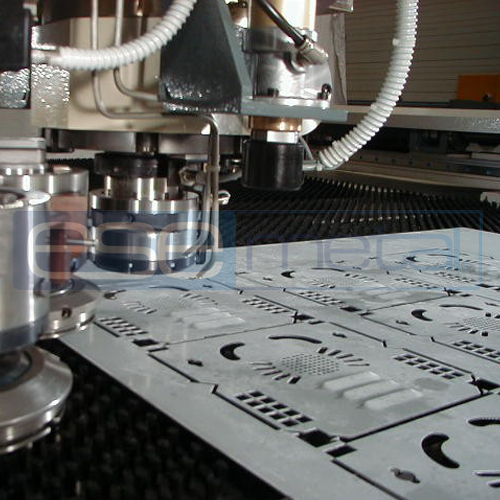

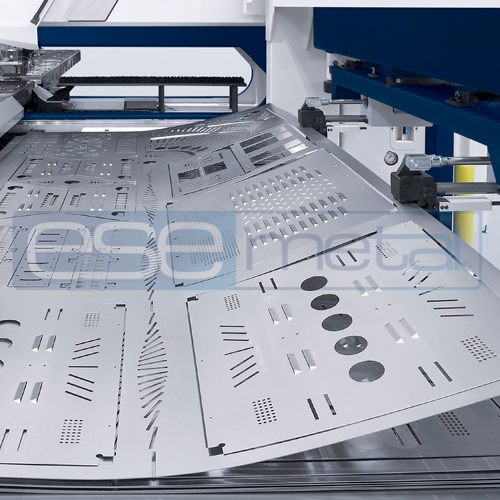

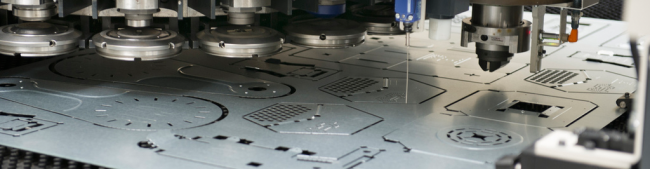

Computer numerically controlled (CNC) punching is a manufacturing process that is carried out by CNC punch presses. These machines can be either a single head and tool rail (Trumpf) design or multi-tool turret design. The machine is basically programmed to move a sheet of metal in an x and y direction so as to accurately position the sheet under the machine’s punching ram ready to punch a hole. The processing range for most CNC punch presses is 0.5mm to 6.0mm thick in a range of materials including steel, zintec, galv, stainless steel and aluminum. The choice of hole punched can be as simple as a circle or rectangle right through to special shapes to suit a specific cut out design.

By using a combination of single hits and overlapping geometries, complex sheet metal component shapes can be produced. The machine may also punch 3D forms such as dimples, taptite® screw thread plunges, and electrical knockouts etc on either side of the sheet, which are often employed in sheet metal enclosure design. Some modern machines may have the ability to tap threads, fold small tabs, punch sheared edges without any tool witness marks making the machine very productive within the component cycle time. The instruction to drive the machine to create the desired component geometry is know as the CNC program.